If you’ve ever smelled your blend on Day 1 and thought, “Uh… this is kinda sharp,” you’re not alone. A lot of fragrance work feels like cooking soup: it tastes rough when everything just hit the pot. Give it time, and the edges soften.

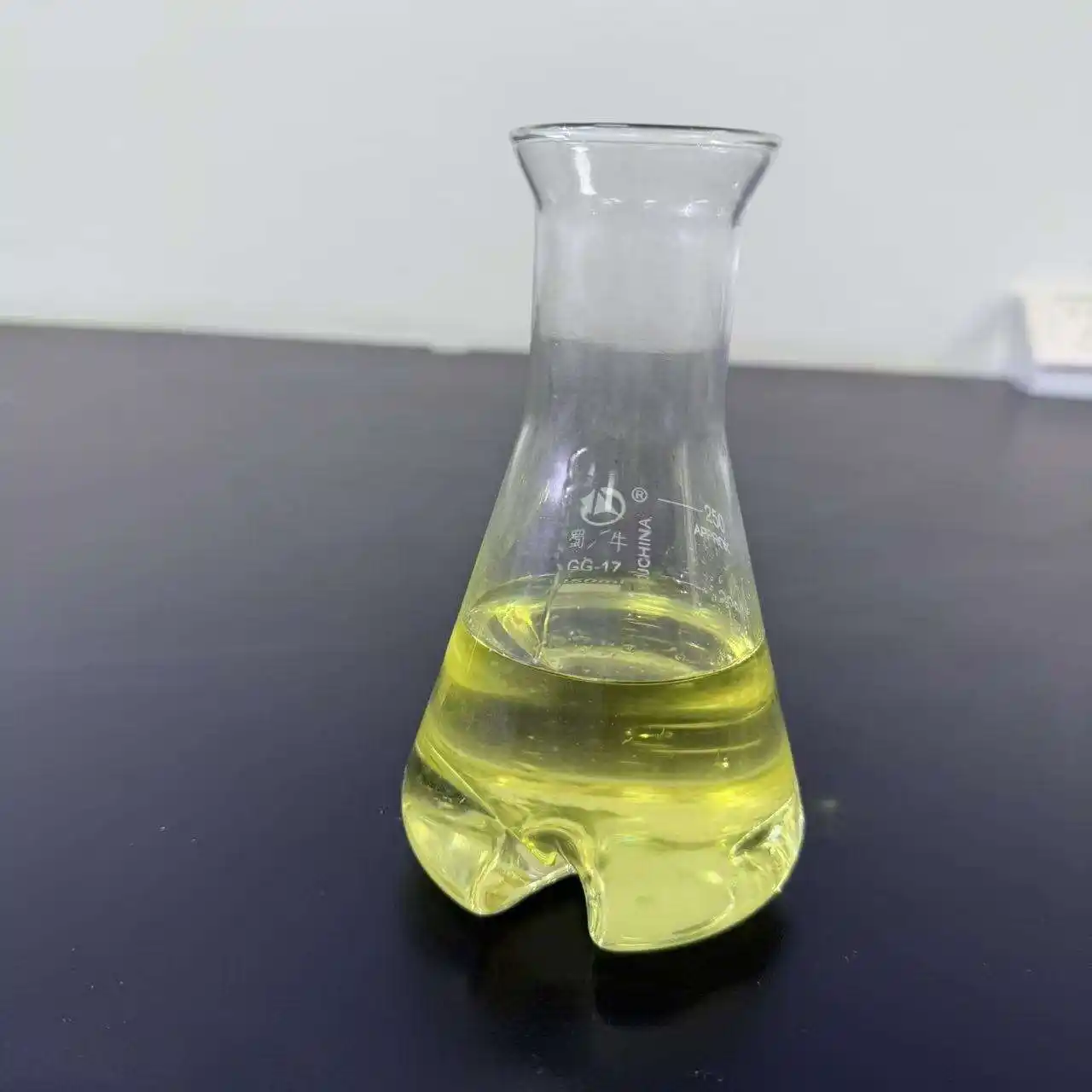

That “give it time” step is what most people call perfume maceration (some folks also call it maturation). And yes, it matters—especially when you’re building fragrance oils for real formats like shampoo, detergent, candles, diffusers, or fine fragrance.

My take (and I’ll argue it): maceration isn’t a vibe. It’s a controlled process. You’ll get better scent smoothness, more stable performance, and fewer “why did this batch smell different?” moments—if you treat maceration like a mini SOP, not a waiting game.

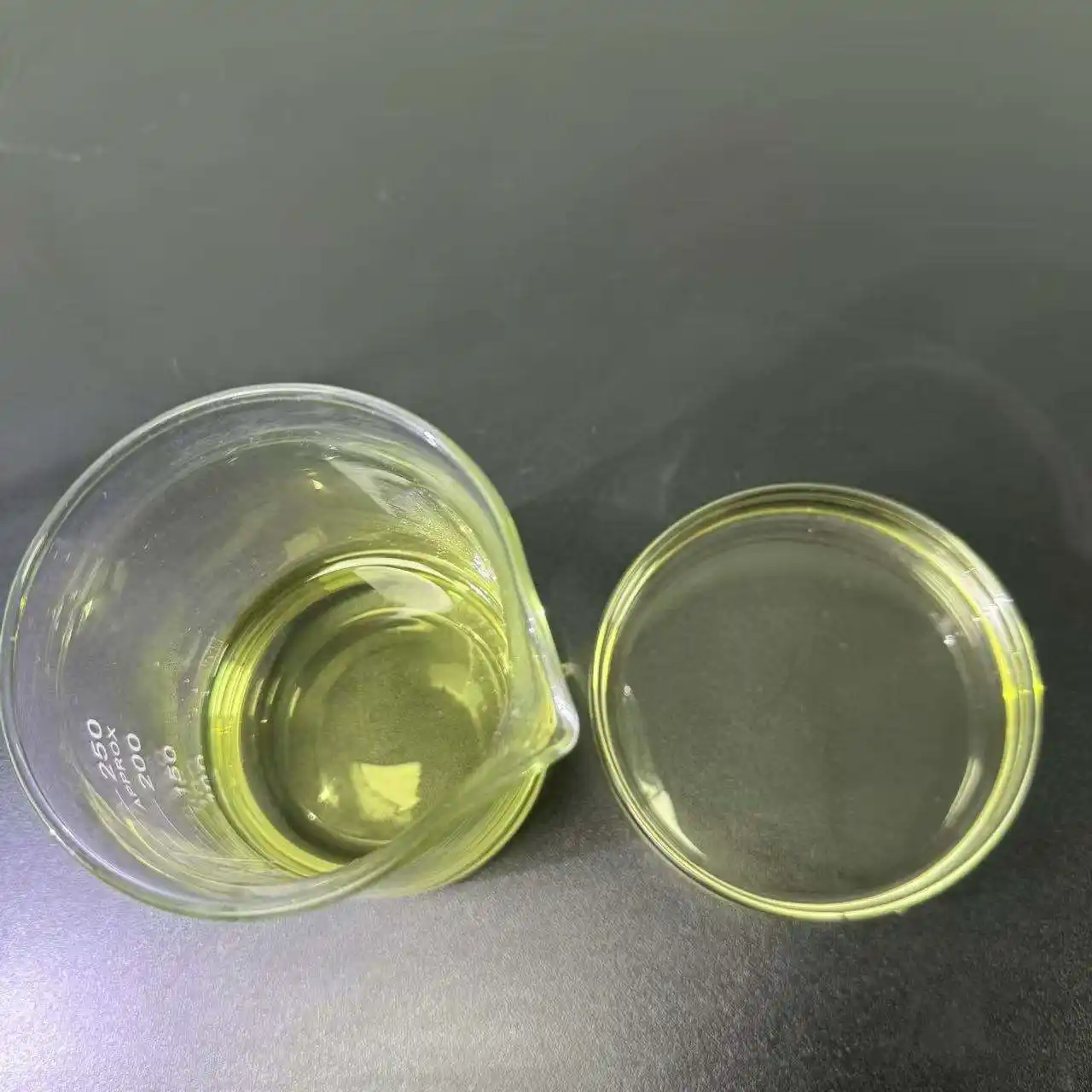

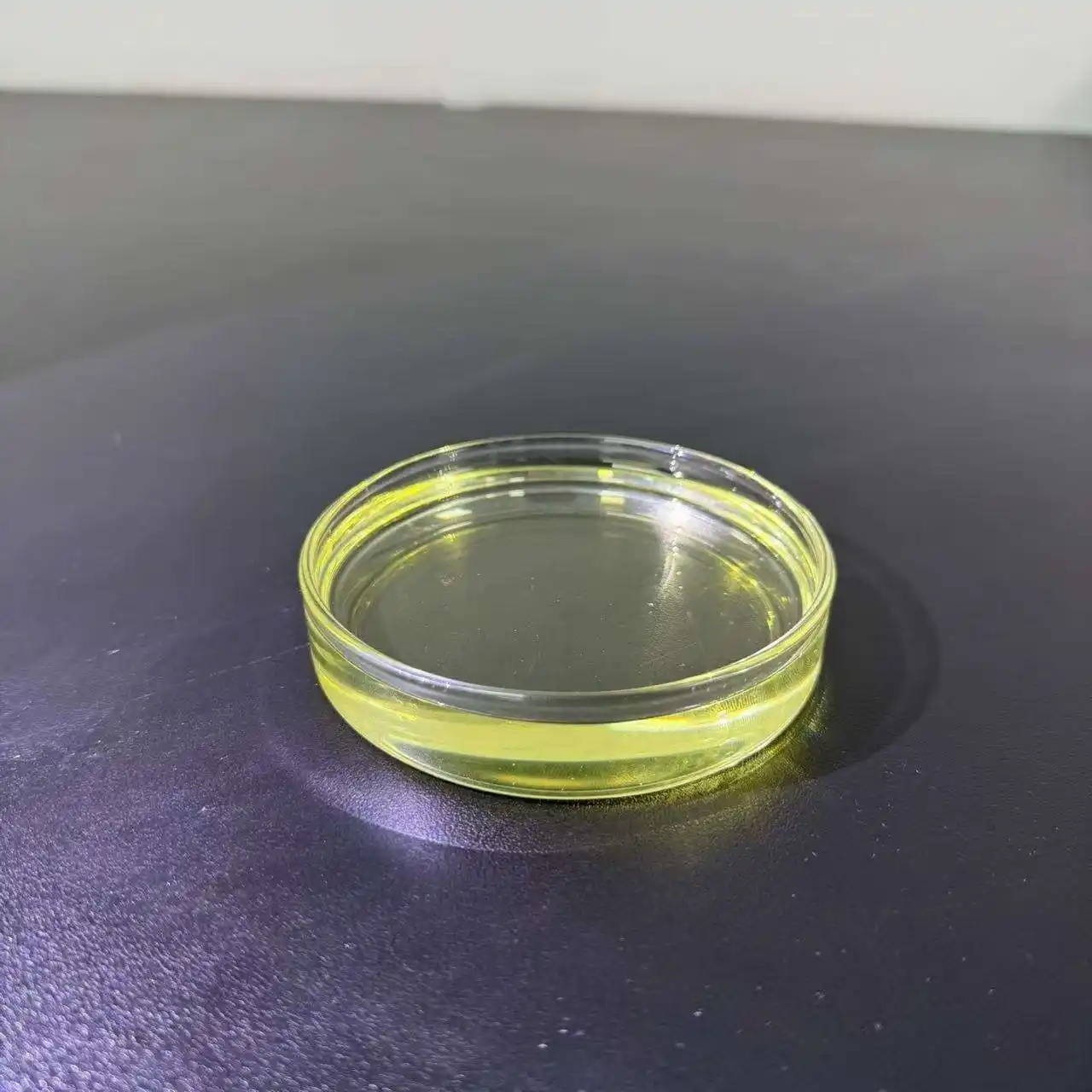

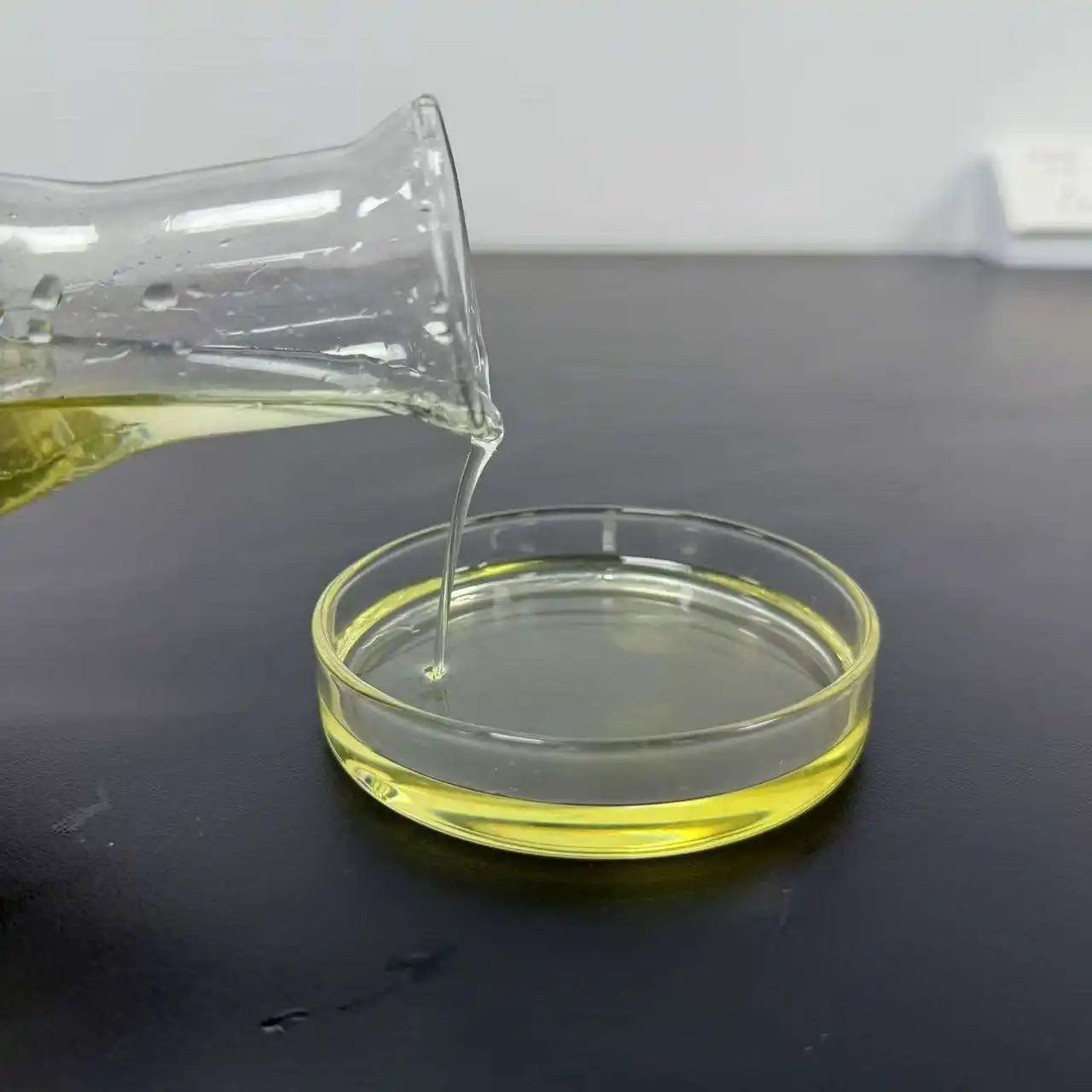

In perfumery, maceration usually means resting the finished blend (fragrance concentrate, EDP/EDT blend, or fragrance oil) so the materials settle into a more stable smell profile. People often report that the scent becomes smoother and more “connected” after rest, especially on the drydown.

Heads-up: “maceration” can also mean soaking raw botanicals in ethanol to make tinctures. In that world, you’re literally extracting aromatics over weeks to months in high-proof alcohol.

Different meaning, same lesson: time changes what you get.

Fresh blends can feel “spiky,” especially when you have bright citrus, aldehydes, or sharp aromachemicals. After rest, that first blast often calms down. It doesn’t always get weaker. It just gets less rude.

When a perfume is new, you might smell parts instead of the whole: “lemon… then something woody… then musk.” With time, the blend tends to read as one idea.

Take a warm woody build like a fine-fragrance base (think amber + woods + musks). On Day 1 it can feel dry or scratchy. After a few weeks, it usually smells rounder on blotter and skin. (That’s one reason fine fragrance makers often sit in the 4–6 week range, and sometimes longer for complex builds.)

Maceration also exposes boring but critical stuff: haze, sediment, off-notes from packaging, or solubility problems. If you skip the wait, you might ship a sample that looks fine today and turns cloudy next week.

Here’s the trap: people hear “more time = better” and they push maceration forever. Sometimes that helps. Sometimes it just… changes things in a direction you didn’t want.

In extraction science, there’s a common idea: you hit a point of diminishing returns where extra time doesn’t increase much anymore. One tincture-focused explanation puts that equilibrium point around 4–6 weeks for many cut-and-sifted herbs.

And even when “more” increases one metric, it can reduce another. A peer-reviewed wine maceration study shows that increasing maceration from 5 to 15 days increased ABTS antioxidant values and total phenolics, while total anthocyanin decreased. That’s a clean example of trade-offs over time.

| Maceration time | ABTS (mg Trolox/L) | DPPH (mg Trolox/L) | Total phenolics (mg GAE/L) | Total anthocyanin (mg Malv/L) |

|---|---|---|---|---|

| 5 days | 59.59 ± 2.68 | 152.90 ± 0.82 | 3131.67 ± 53.33 | 347.13 ± 3.25 |

| 10 days | 68.72 ± 2.44 | 153.83 ± 0.24 | 2955.42 ± 32.03 | 272.41 ± 17.88 |

| 15 days | 72.86 ± 2.49 | 135.92 ± 0.72 | 3866.04 ± 77.19 | 242.53 ± 1.63 |

Why this matters for perfume: rest time can smooth harshness, but it can also dull sparkle if you let it run too long or store it wrong. Your job is not “wait forever.” Your job is pick the right timeline and hit checkpoints.

You’ll see a lot of ranges online. The ones that show up again and again for perfume maceration land around 4–6 weeks for professional-style results, with complex blends stretching longer.

For tinctures and raw-material soaks, it can run weeks to months in high-proof ethanol.

Here’s a practical cheat sheet you can hand to your R&D or QA team.

| Format / use case | Typical maceration time | Checkpoints you should log | What usually changes |

|---|---|---|---|

| Fine fragrance (EDP/EDT) | 4–6 weeks (up to ~12 for complex) | 48–72h, 2w, 4w, 6w | Top harshness drops, drydown blends better |

| Fragrance oil concentrate (before adding to base) | 1–2 weeks (often enough for evaluation) | 72h, 7d, 14d | Accord reads cleaner, mods become clearer |

| Surfactant systems (shampoo, body wash, dish soap, detergent) | 3–7 days for stability read, 2–4 weeks for “true smell” | 24h, 72h, 7d, 14d | Solubility issues appear; “clean” note may shift |

| Candles (wax cure, not ethanol maceration) | 1–2 weeks cure (varies by wax) | 48h, 7d, 14d | Throw improves; harsh notes settle |

| Diffusers / air care | 1–2 weeks | 72h, 7d, 14d | Blend smooths; diffusion character stabilizes |

No, these aren’t laws of physics. They’re working ranges that keep you from doing the classic mistake: judging a scent too early, then chasing it with endless “mods.”

Store samples in consistent conditions: cool-ish, dark-ish, stable temperature. Label everything. Sounds basic, but I’ve seen teams lose weeks because two bottles aged in two different corners of the lab.

Mix well at the start. After that, let it sit. Constant agitation can keep micro-bubbles and haze suspended, which makes you think the blend is unstable when it’s just… not settled yet.

Pick your routine: blotter at 0h/2h/8h, plus a skin check if it’s fine fragrance. For functional fragrance oils, smell it in the base, not only neat. Your customer buys performance in the product, not the concentrate.

Here’s some industry slang that saves your sanity: don’t over-mod.

Set windows like “no formula changes until the 7-day read,” then again at 14 days. Otherwise you’ll end up fixing problems that time would’ve solved.

That’s usually a matrix problem. Surfactants can mute certain notes, and some materials bloom later. Let it sit, then evaluate at 72 hours and 7 days in the actual base. If it still falls flat, you adjust the structure (often more substantive backbone, not more top sparkle).

Classic solubility window issue. The blend may look fine right away, then haze out as it equilibrates. A short maceration period helps you catch it before you ship a sample and get that awkward email.

Sometimes it’s raw material variation. Sometimes it’s rushed blending + no rest. Either way, the fix is boring: QC sniff panels + traceability + a consistent maceration hold. (Yes, boring works.)

If you’re building for personal care, cosmetics, home care, fine fragrance, candles, or air care, you don’t want to wait forever—but you also can’t skip stabilization.

That’s where a supplier with real systems helps. On I’Scent’s side, the pitch is straightforward:

So the idea isn’t “rush everything.” It’s: get fast sampling, then run maceration checkpoints like a pro so you don’t burn weeks in back-and-forth.

If you want to see where this plugs into your product type, these pages map cleanly to real formats: