Sample rounds can feel like a treadmill. You start with energy, then you hit round 4 and everyone’s notes get vague: “Make it more premium,” “less sharp,” “more clean but also warmer.” That’s when timelines slip, teams argue, and your launch turns into a moving target.

Here’s the truth: you don’t cut rounds by “trying harder.” You cut rounds by removing ambiguity—before the first vial even ships. That means tighter inputs, cleaner feedback, better testing in the real base, and solid change control.

Below is a practical, repeatable way to lock a formula fast—without cutting corners.

If you’re building for specific product scenarios, these pages show what I’Scent supports:

Most “too many rounds” problems are brief problems. A soft brief forces the perfumer to guess. Then you react to the guess. Then your reaction becomes the next brief. That loop can go forever.

A brief you can execute makes the first submission much closer to what you meant.

Use this checklist. Keep it simple. Keep it specific.

| Brief item (must-have) | What “good” looks like | What it stops |

|---|---|---|

| Product category + base | “Shampoo, surfactant-heavy, clear system” / “Bar soap, high pH” / “Soy candle” | A great blotter that fails in formula |

| Target vibe (one sentence) | “Clean green tea + airy musk, not laundry, not powder” | Endless direction changes |

| No-go list | “No coconut, no baby powder, no harsh aldehydes” | Random off-brief turns |

| Performance KPI | “Strong bloom at 1h, soft skin musk at 6h” / “Hot throw must pop” | “Smells nice but weak” feedback |

| Benchmark scents | 2–4 references + what to copy / avoid | People fighting over adjectives |

| Compliance + docs | IFRA need, SDS/MSDS, COA, allergens | Late-stage reformulation |

Little tip: don’t write “luxury.” Write the smell behavior you want: texture, lift, warmth, dryness, sparkle, creaminess. Perfume is chemistry, not mood boards.

If five people can veto the scent, you’ll never lock it. You’ll just keep “modding” until it becomes average.

Do this upfront:

That might sound strict, but it’s actually freeing. It keeps feedback sharp and prevents decision fatigue.

“Fresh” can mean citrus, shampoo, watery melon, cold air, or soap. Same word, five meanings. That’s why rounds explode.

Benchmarks fix this fast:

Example of usable language:

This is also where industry slang helps. Talk like you mean it:

If your note can’t lead to a change, it’s just a feeling. Feelings are fine, but they don’t steer a lab.

Lock your evaluation method:

Use fixed check-ins:

| Dimension | 1 (low) | 3 (ok) | 5 (strong) | Delta notes (what to change) |

|---|---|---|---|---|

| Clarity | muddy | acceptable | crisp | “remove waxy haze” |

| Diffusion (bloom) | shy | normal | projects | “more aura at 1h” |

| Longevity | fades fast | decent | stubborn | “drydown drops too early” |

| Brief match | off | close | on-target | “less laundry, more tea” |

| Off-notes | obvious | minor | none | “plastic note in base” |

A blotter is a preview, not the truth.

Different carriers stress a scent in different ways:

So your process should match your product scenario:

Do both, but don’t let blotter override base truth. If it dies in formula, it dies. Period.

Cold throw sells the first sniff. Hot throw earns repeat buys. Test both, and log them separately. If you mix those notes, you’ll chase your tail.

Late surprises create the worst extra rounds:

Do basic stability checks early:

You don’t need perfection. You need early warning.

If you don’t track versions, you’ll argue about ghosts:

Run this like a real project:

This also protects batch-to-batch consistency later. When you reorder, you want the same smell, not a surprise.

Compliance shouldn’t be an afterthought. If you wait till the end, you may discover your “final” formula can’t ship to your market without changes. That adds extra cycles, guaranteed.

Get the document pack aligned while you iterate:

For reference on how these docs fit into real production workflows, see:

MSDS and COA certifications

| Document | When to request | Why it matters |

|---|---|---|

| IFRA statement | early (before “final”) | stops last-minute reformulation |

| SDS/MSDS | early-mid | shipping + safety readiness |

| COA | at production | confirms specs per batch |

| Allergen info | early-mid | label planning, market readiness |

You don’t need 10 rounds. Most projects can lock in 3 if your inputs and feedback are clean.

Here’s a simple workflow:

| Round | Goal | What you send back | What you don’t do |

|---|---|---|---|

| Round 1 (direction) | pick the lane | scorecard + 3 deltas max | don’t ask for a new theme |

| Round 2 (tighten) | reduce gaps | updated deltas only | don’t re-open Round 1 debates |

| Round 3 (polish + lock) | finalize | micro-notes + sign-off | don’t “just try one more idea” |

If Round 2 still feels like a direction fight, pause. Fix the brief and benchmarks. Otherwise round 7 will show up real quick.

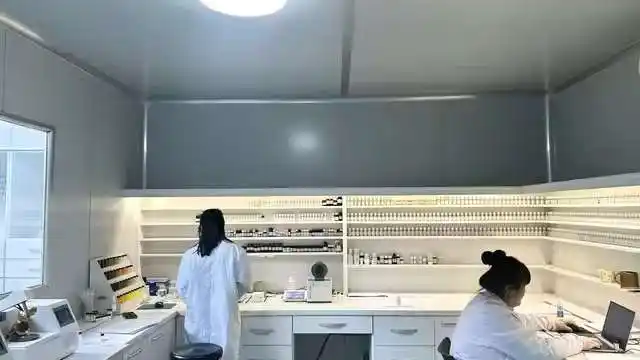

When you run this process well, speed becomes a weapon (not a mess). I’Scent is built for that.

What I’Scent brings to the table:

If your project is fine fragrance, start here: Fine Fragrance

If you need a broader catalog first: Wholesale Fragrance Oils

If you want full customization + manufacturing support: OEM/ODM Perfume Oil solutions

Want to move fast? Send a tight brief and your benchmarks. We’ll do the rest.

Contact I’Scent