You’re building flavor for things people actually swallow. That means your “nice smell” can’t stop at nice. It has to meet food-use rules, pass plant safety checks, and stay consistent from bench to scale. In short: COA proves the batch; SDS keeps people safe; GRAS and labeling rules keep the product lawful. Let’s make this practical, simple, and hands-on—and show where I’Scent fits in as your OEM/ODM Fragrance Oil Manufacturer for Food & Beverage and Wholesale & Custom Bakery Fragrances | Tailored Scents for Your Creations.

A COA confirms the actual numbers for a particular lot. It doesn’t bless ingestion on its own. You still have to check whether each component is appropriate for food scenarios.

What you should expect on a COA for flavor-direction oils

Quick tip: When numbers sit too close to spec edges, request trend data across lots. You want buffer, not nail-biting.

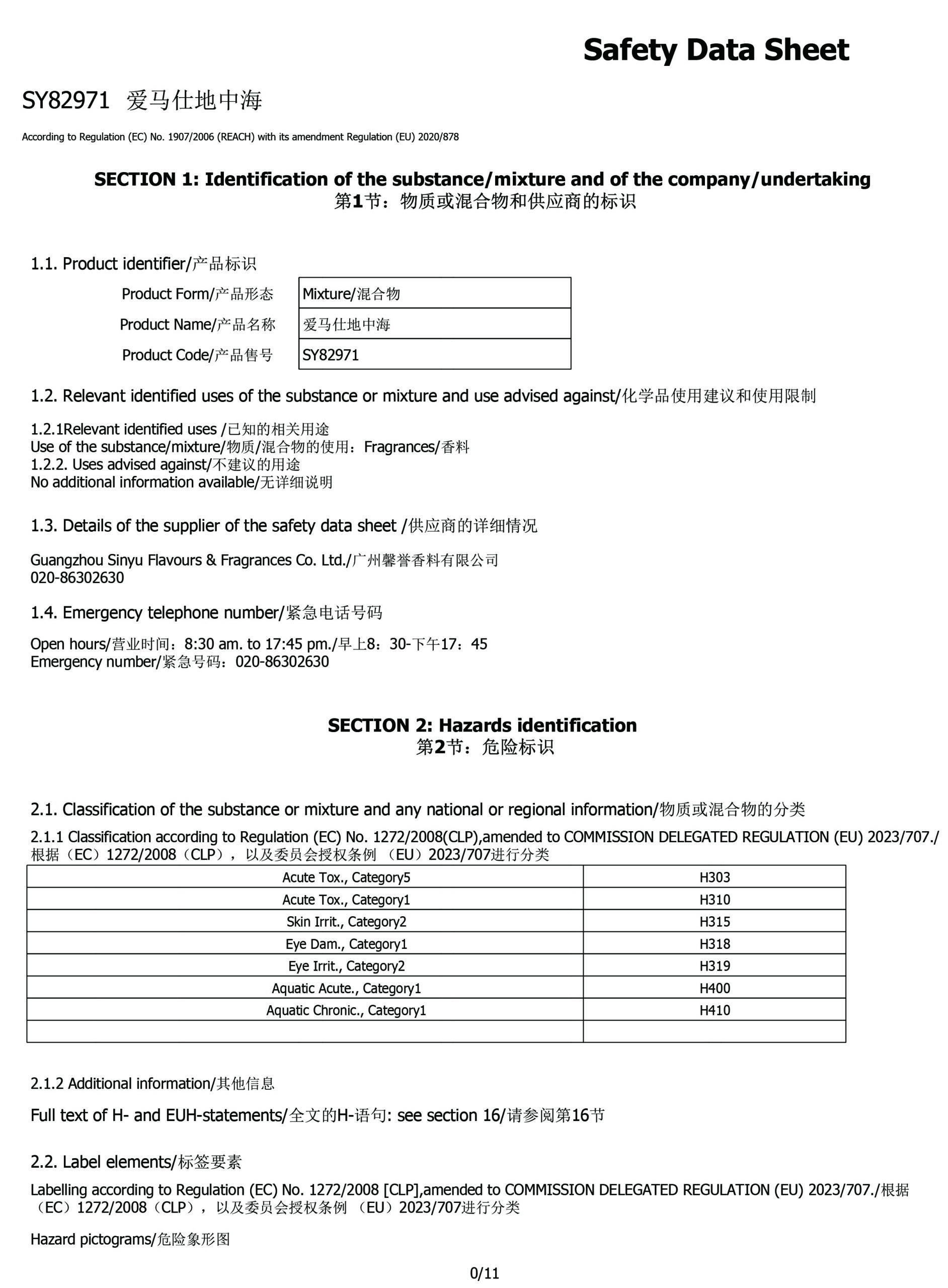

An SDS (formerly MSDS) tells your EHS team how to handle, store, and respond to spills or exposure. It protects operators and the facility. It does not certify food suitability.

Look for in SDS

Plant reality: If the SDS calls for local exhaust or tight temp controls, bake that into your SOP, not just a wall poster. Training beats wishful thinking.

If you intend ingestion, check your flavor ingredients against FEMA GRAS or applicable food-additive frameworks. Don’t mix up “fragrance” with “flavor.” Fragrance standards (like IFRA) mostly live in leave-on/rinse-off worlds. Food sits under a different umbrella.

Practical checkpoints

Reality check: “Food-grade essential oil” isn’t a magic phrase. You still validate dose and route. Too high? Off-notes, safety flags, or both.

You can’t call it whatever. 21 CFR 101.22 sets how you name the flavor on pack. The idea is simple: name reflects what’s in there and where the characterizing taste comes from.

Common naming lanes

Keep marketing and regulatory on the same page. It saves relabeling and rework, for real.

IFRA is great for cosmetics, home fragrance, and personal care risk assessments. It’s usually not your ingestion ticket. Treat “compliant to IFRA” as nice-to-have for non-food lines, not a substitute for GRAS/food-additive logic.

Carriers matter. Propylene Glycol (PG) and Triacetin are common flavor carriers with established food use. They help solubilize actives, improve dosing, and stabilize top notes through heat steps.

Watch-outs

Dose to the matrix, not to the logo.

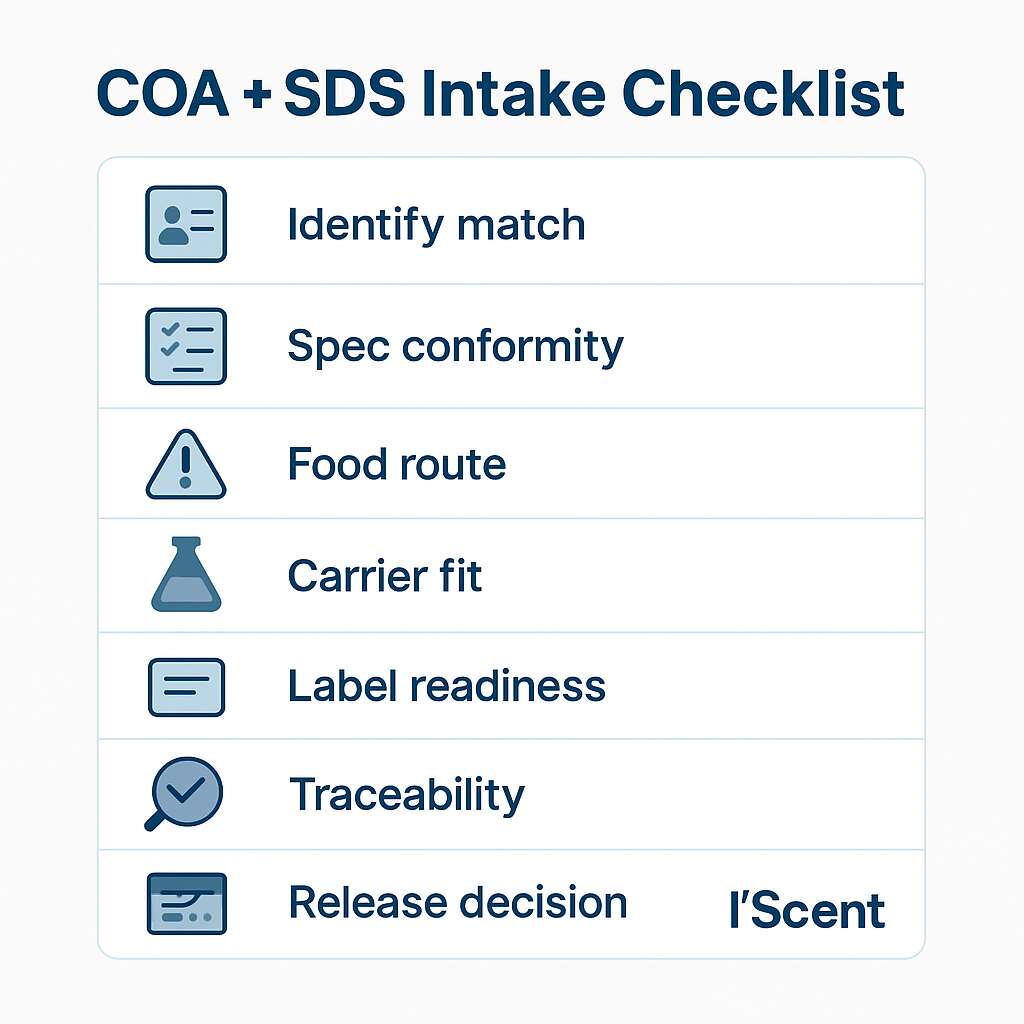

| Gate | What to Verify | Document | Pass Criteria | Shop-Floor Note |

|---|---|---|---|---|

| Identity match | Item name, lot/Batch ID, ERP code | COA, label | Exact match across docs | Kill switch if mismatch |

| Spec conformance | SG, RI, acid value, colour, GC-MS markers | COA | Within spec bands, no outliers | Request trend if edge-hugging |

| Food route | Flavor vs fragrance route clarified | Tech sheet, supply scope | Declared for flavor use | “Fragrance-only” → no go for ingestion |

| Hazard controls | PPE, ventilation, storage temp | SDS | Controls feasible on line | If not feasible, re-route or re-engineer |

| Carrier fit | PG/Triacetin or alt, matrix fit | COA/formula note | Compatible with target system | Check haze, flash-off, bloom |

| Label readiness | Natural/Artificial naming path | 21 CFR 101.22 review | Claim matches composition | Align MKT + RA early |

| Traceability | Lot trace, mock recall window | ERP record | Full chain from raw to ship | Drill a 2-hour mock recall |

| Release decision | Sign-off, hold, or reject | QA release form | Documented rationale | No sign-off, no fill—simple |

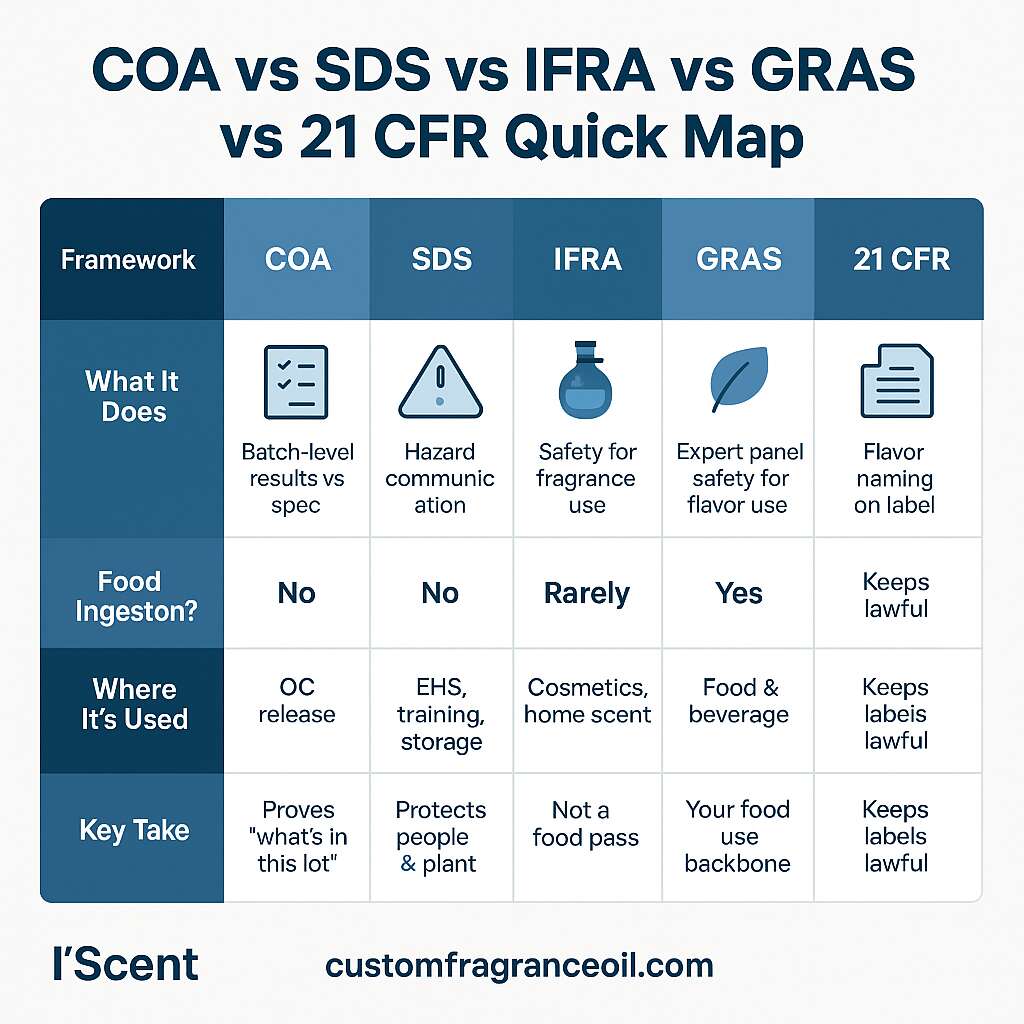

| Framework | What it Does | Food Ingestion? | Where it’s used | Key Take |

|---|---|---|---|---|

| COA | Batch-level results vs spec | No | QC release | Proves “what’s in this lot” |

| SDS | Hazard communication | No | EHS, training, storage | Protects people & plant |

| IFRA | Safety for fragrance use | Rarely | Cosmetics, home scent | Not a food pass |

| FEMA GRAS | Expert panel safety for flavor use | Yes | Food & beverage | Your food-use backbone |

| 21 CFR 101.22 | Flavor naming on label | Yes | Packaging & claims | Keeps labels lawful |

Pin this chart in QA, Regulatory, and Procurement. One glance, fewer mix-ups.

These aren’t stories; they’re recurring shop-floor realities. You’ll save time by planning for them.

Don’t choose between tongue and instrument. Use both.

When the nose says “nice” but the GC says “shift,” act. Numbers plus noses win.

| Scenario | Composition Reality | On-Pack Naming Direction |

|---|---|---|

| Strawberry RTD, natural actives drive character | Natural strawberry-type flavor with natural carriers | Natural strawberry flavor |

| Strawberry hard candy, natural + synthetic combined | Mixed natural + artificial strawberry key notes | Natural and artificial strawberry flavor |

| Citrus drink, only synthetic citral/linalool route | Artificial only | Artificial citrus flavor |

You’ll keep QA, RA, and Marketing aligned if you pick the naming path during the R&D brief, not at artwork time.

Food safety isn’t only paperwork. It’s drills.

At I’Scent, our advanced ERP gives you full lot trace. You’ll know exactly what went in, and which orders used it. That makes audits less scary.

Want tailored work? Explore Tailored Scents and Perfume Raw Materials on our site, or just ping the team.

Short, but it holds.

As a Fragrance Oil Supplier and OEM/ODM Fragrance Oil Manufacturer since 2005, I’Scent focuses on two things that genuinely reduce risk: precision and speed. Precision means repeatable lots, documented COAs, and SDS that match plant reality. Speed means you test, learn, and scale before the season changes.

When you’re developing Food & Beverage flavors or Custom Bakery Fragrances, you need more than aroma. You need a system that keeps working when the line runs hot, cold, or just… weird. We help you do that.