You want flavor that sells, and you want it Halal. Good. Let’s keep it simple, clear, and real-world. Below I’ll map the rules, the typical limits on ethanol, the safe carrier picks, and the plant controls that stop cross-contact. I’ll also show where I’Scent fits in—fast sampling, tight traceability, and compliant docs—so your product ships clean and on time.

(Heads-up: in food, people say “fragrance oil,” but the correct term is food flavoring. That’s our baseline here.)

Food & Beverage flavorings must be food-grade. Period. That means you check them against core food law first, then layer Halal on top.

If it’s not compliant as food flavoring, it doesn’t belong in a drink, syrup, confection, glaze, or bakery filling—no matter how great it smells.

Quick SEO-friendly pointers you can click inside our site:

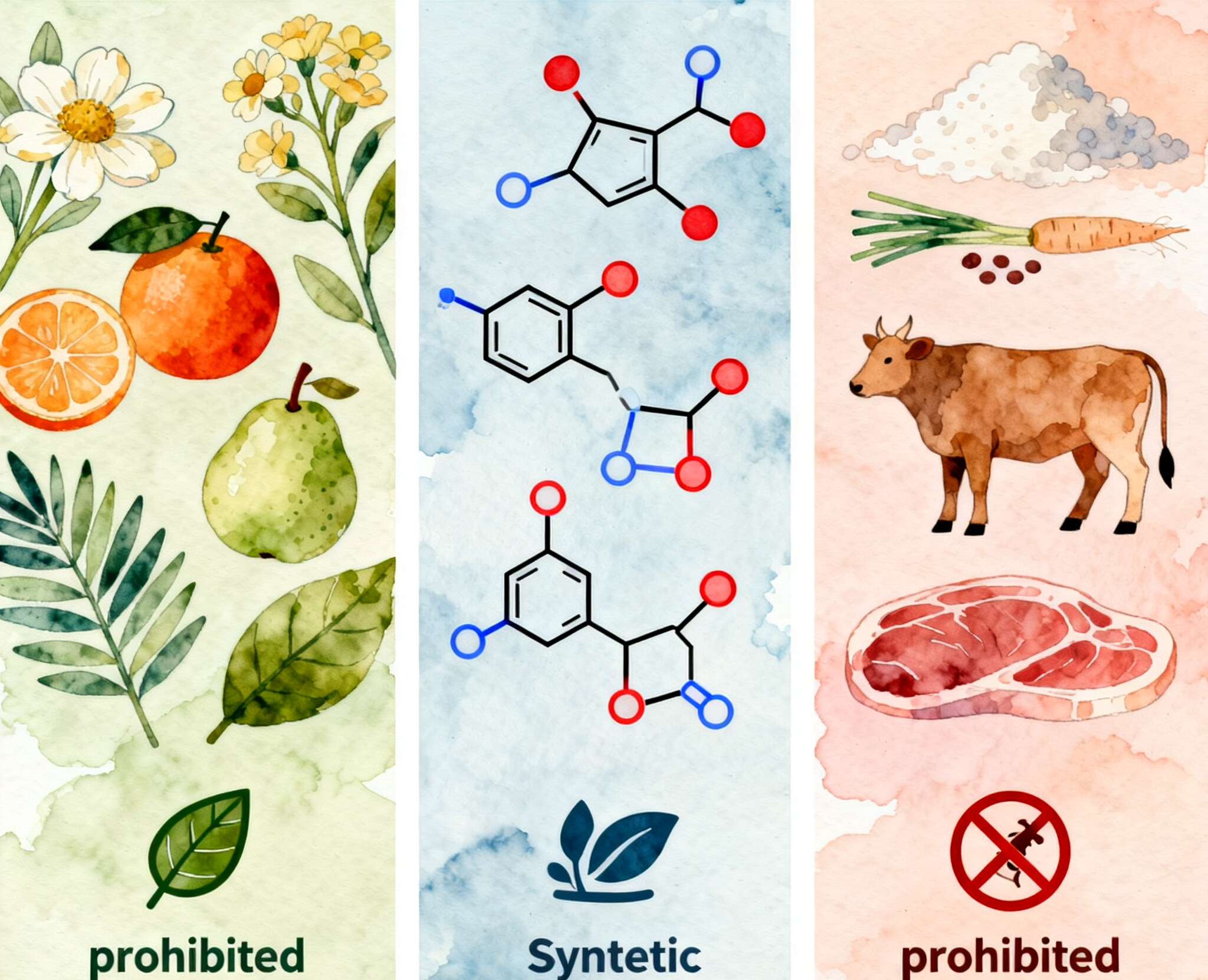

Once food-grade is locked, Halal compliance focuses on source, residuals, and process control:

These aren’t “nice-to-haves.” They’re the gates to market entry.

The following table summarizes common practice you’ll meet in audits and buyer questionnaires. Keep it printed in your spec pack.

| Topic | Limit / Expectation | Where It Applies | Practical Note |

|---|---|---|---|

| Ethanol in the flavor | ≤ 0.5% | Flavor concentrate only | Solvent use, not a taste driver. Record the calculation. |

| Ethanol in finished goods | ≤ 0.1% | Ready-to-consume product | Verify with mass balance or lab COA on pilot. |

| Ethanol source | Non-khamr | Raw material origin | Ask for origin statements; keep supplier letters on file. |

| Use case | Technical solvent | Process step | Don’t pitch it as an “ingredient.” It’s a vehicle. |

Pro tip: during commercialization, run a simple spreadsheet mass-balance (or LIMS calc) to confirm the finished-good number. Don’t overcomplicate it; do it early.

You don’t need ethanol at all times. Many flavor systems run great on non-alcohol carriers.

| Carrier / Solvent | Halal Suitability (Typical) | Common Use in F&B | Pros | Watch-outs |

|---|---|---|---|---|

| Propylene glycol (PG) | Generally acceptable | Beverages, syrups, emulsions | Stable, easy handling, broad solubility | Heat pickup in cook steps; spec limits vary by market. |

| Triacetin (E1518) | Generally acceptable | Bakery flavors, beverage bases | Good solvent for esters; clean taste | Viscosity shifts in cold rooms; check dosing window. |

| Ethanol | Conditional | Flavor extraction, dilution | Fast solubilization | Source must be acceptable; keep ≤0.5% (flavor) / ≤0.1% (finished). |

If your brand claims “zero alcohol,” pick PG or triacetin first and validate sensory. If you must use ethanol (extraction, top notes), set the guardrails and document the math. Easy.

Paperwork alone won’t pass. Auditors look for process evidence. Here’s the short list that keeps lines clean and compliant:

If this sounds like your existing food safety program—great. Halal dovetails with GMP and ISO style systems. You’re just tightening a few sensitive points.

Auditors and brand QA teams like clean stacks. Here’s the pack we ship with flavor projects:

| Document | Why It Matters | What To Check Fast |

|---|---|---|

| Halal Certificate (valid, current) | Market access; logo use | Issue date, scope, product list, cert body. |

| IFRA Certificate | Allergen / safety disclosure | Version, usage category, dose ceiling. |

| COA per lot | Identity, assay, organoleptics | Lot number match, spec limits, sign-off. |

| SDS | Storage, handling, hazard | Rev date, emergency info. |

| Ingredient & origin statements | Alcohol/animal source control | Explicit “no prohibited source” line. |

| Batch trace via ERP | Recall readiness | In/Out mapping by lot; timestamps. |

Our ERP traceability ties raw material intake → compounding → QC release → shipment. That reduces audit ping-pong and shortens the approval cycle.

Useful internal resources:

Beverage base, clear drink.

You need bright top notes without haze. Go PG or triacetin as the primary vehicle; if you require ethanol for a delicate extract, keep it technical and prove the ≤0.1% in the final bottle. Run organoleptic checks and a quick headspace GC if your lab has it. No drama, just math.

Bakery filling and frosting.

Heat can mute light notes. Use triacetin for stability and late-stage addition to cut thermal loss. Don’t forget line clearance on the depositor; frosting lines love to carryover. Keep a retention of the first post-CIP batch.

Confection syrup (hard candy or lollipop).

High solids, high temp. PG carries many esters cleanly here. Validate in a bench kettle first. Watch micro load on cooling; it’s usually fine, but QA will ask.

These aren’t “stories,” they’re day-to-day jobs your ops and QA teams already see. The twist is simply proving Halal control while protecting taste.

Print this, tape it to your monitor:

I’Scent is an OEM/ODM fragrance oil & perfume raw materials manufacturer with a large Food & Beverage bench. Since 2005, we’ve built more than 40,000 flavor & scent formulas and keep improving them with a deep sensory library. What that means for you:

We don’t push a magic bottle. We scope your use case, dose, process window, and label claim, then pick a carrier that fits—PG, triacetin, or ethanol within solvent limits—and prove the numbers. If you need fragrance replication for a bakery or beverage line, we run a tight side-by-side with your benchmark, tune it, and validate on your actual process. No fluff, just work.

Explore and brief us here:

| Topic | What to Say | Value to Buyer |

|---|---|---|

| Food-grade first | Compliant with food flavor rules before Halal | Safer global access; fewer reformulations |

| Ethanol rules | ≤0.5% in flavor; ≤0.1% in finished goods; non-khamr source | Clear green/red lines; label-claim clarity |

| Carrier pick | Prefer PG / triacetin; ethanol only as needed | Keeps “alcohol-free” routes open; stable taste |

| Plant controls | Line clearance, CIP/SIP, segregation, QC hold, MOC, retentions | Audit-ready; lower recall risk |

| Doc stack | Halal + IFRA + COA + SDS + origin letters | Cuts onboarding time; speeds approvals |

| I’Scent service | 40,000+ formulas, 98% match, fast samples, ERP trace | Faster launches, fewer surprises |