Let’s keep this real. When you say “natural fragrance oils” for food and drinks, buyers read “natural flavors” or “essential oils.” Same family, different label. In food, compliance matters first, story second, and taste always. You want clean label, stable flavor, fast scale-up, and no drama on audits. Yep, that’s the brief.

Below I unpack the big trends using industry keywords you already search for: clean label natural flavors, essential oil nanoemulsions, microencapsulation (spray drying), supercritical CO₂ extraction, upcycled ingredients, FDA 21 CFR 101.22, EU 1334/2008, allergen labeling, Halal certification, IFRA/ISO/GMP. I’ll show the “why,” the “how,” and where I’Scent fits in as a build-partner, not a vendor.

Quick note: we’ll say “natural flavor oils” here, but on your spec sheets and labels use natural flavors / essential oils per local regs.

Clean label is not a slogan. It’s a filter that cuts anything artificial, vague carriers, and messy allergen statements. The result: you need natural flavor systems that survive heat, pH swing, and shelf life without strange aftertastes or label hairballs.

Pain point talk: fewer E-numbers, PG-free or ethanol-free carriers where needed, short decks, and a clear Contains line if allergens apply. If you sell globally, align your language with FDA 21 CFR 101.22 and EU 1334/2008 so regulatory never kicks it back last minute.

Where I’Scent helps: our library (40,000+ formulas) gives you ready base notes, then we tweak topnotes to your matrix. Samples in 1–3 days, production in 3–7 days, MOQ 5 kg (custom 25 kg). That speed means you don’t stall line trials.

Links you may need for SEO or quick sharing:

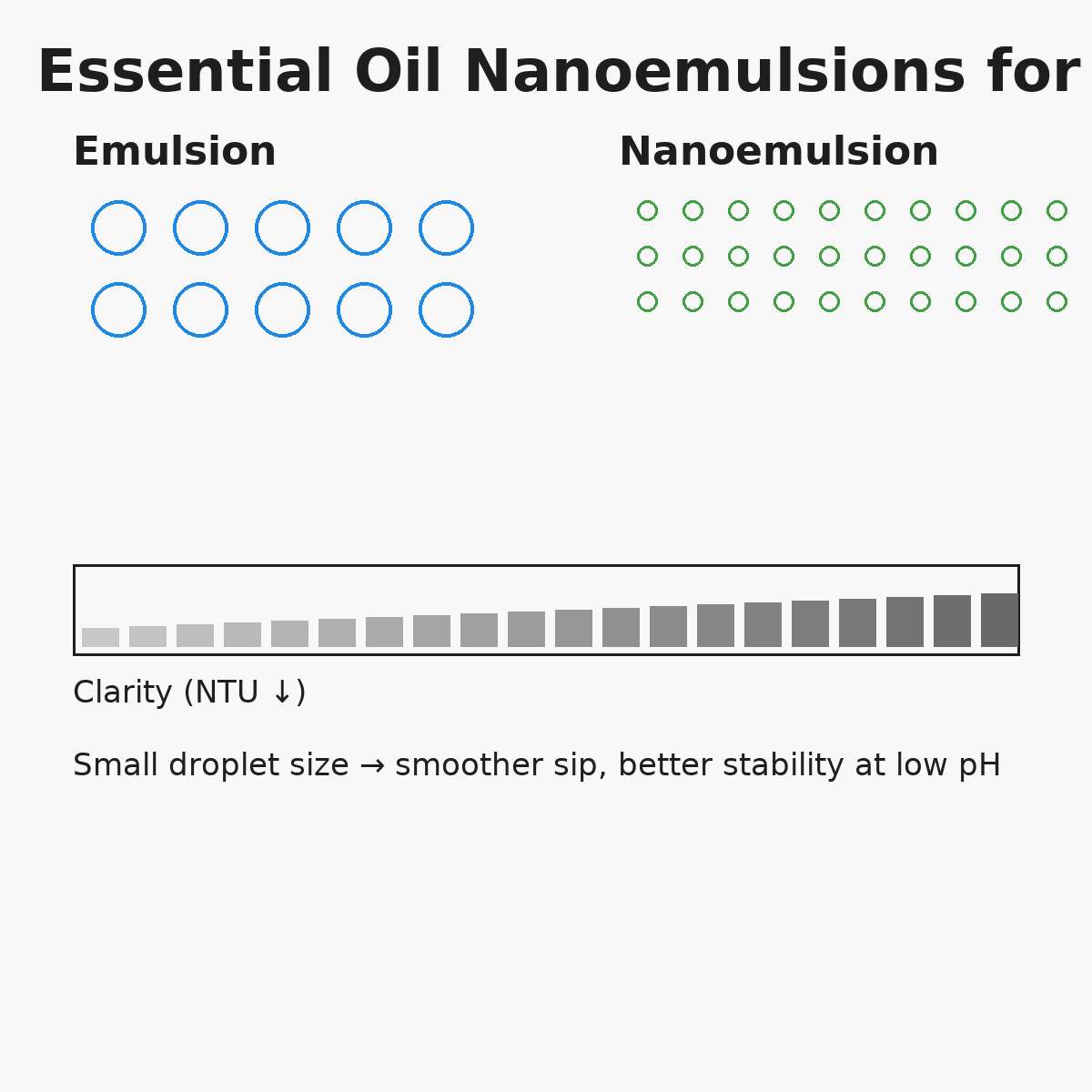

Keyword focus: essential oil nanoemulsions, beverage clarity, droplet size, emulsifier systems

Oil and water don’t like each other. Nanoemulsions make them behave. You get transparent or low-haze drinks, smoother sip, and better flavor persistence at lower loading. Think citrus, mint, spice, florals in RTD teas, energy drinks, non-alc cocktails.

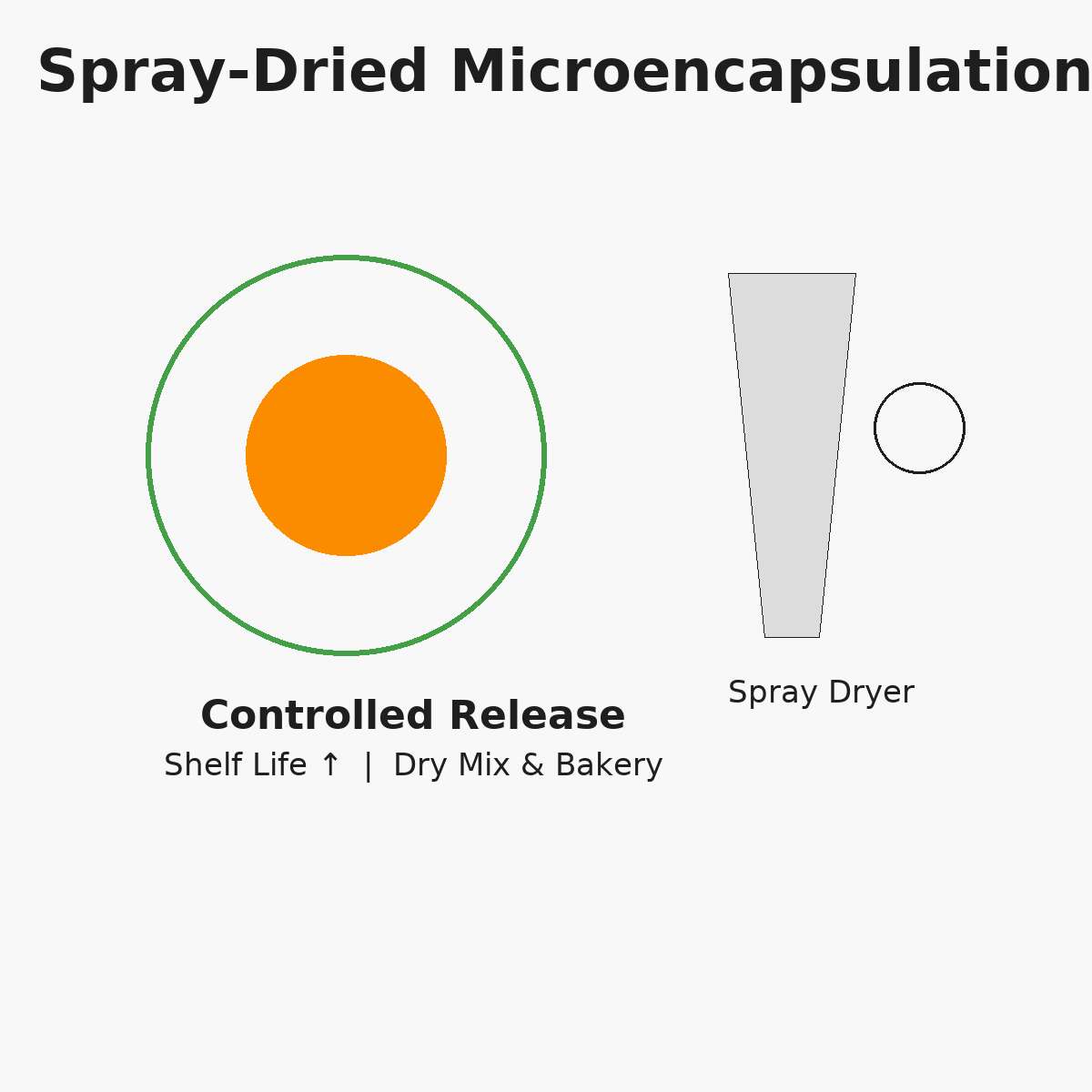

Keyword focus: microencapsulation, spray drying, maltodextrin, gum arabic, controlled release, water activity

Dry formats love spray-dried flavor oils. You protect volatiles, cut oxidation, and time the release for baked goods, dry mixes, instant beverages, confectionery.

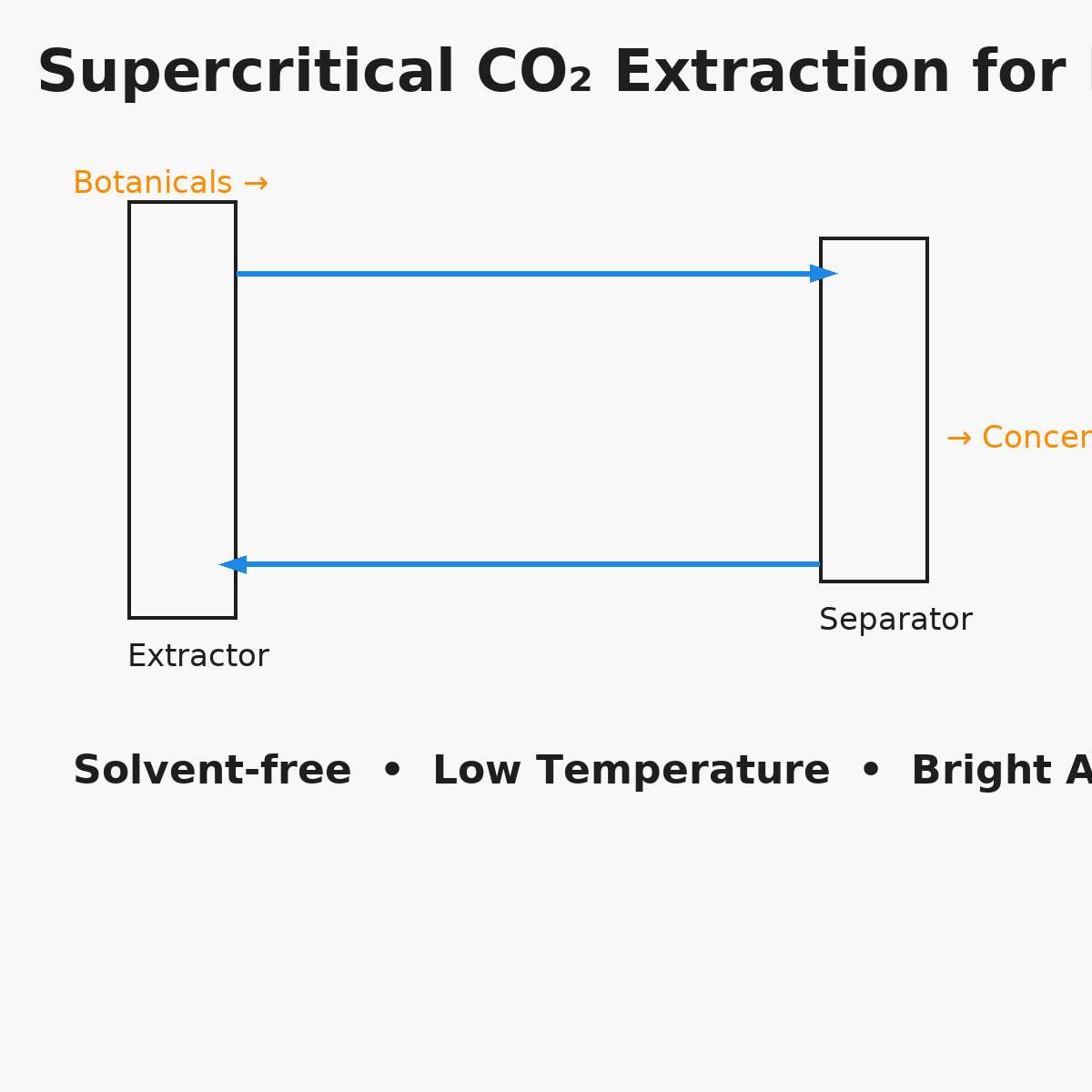

Keyword focus: supercritical CO₂ extraction, solvent-free, low-temperature extraction, terpenes retention

CO₂ pulls delicate aromatics with low heat and without residual solvents. It helps you hold a “solvent-free” claim and a brighter organoleptic profile. Great for citrus, herbs, spices, and any “fresh” tonality.

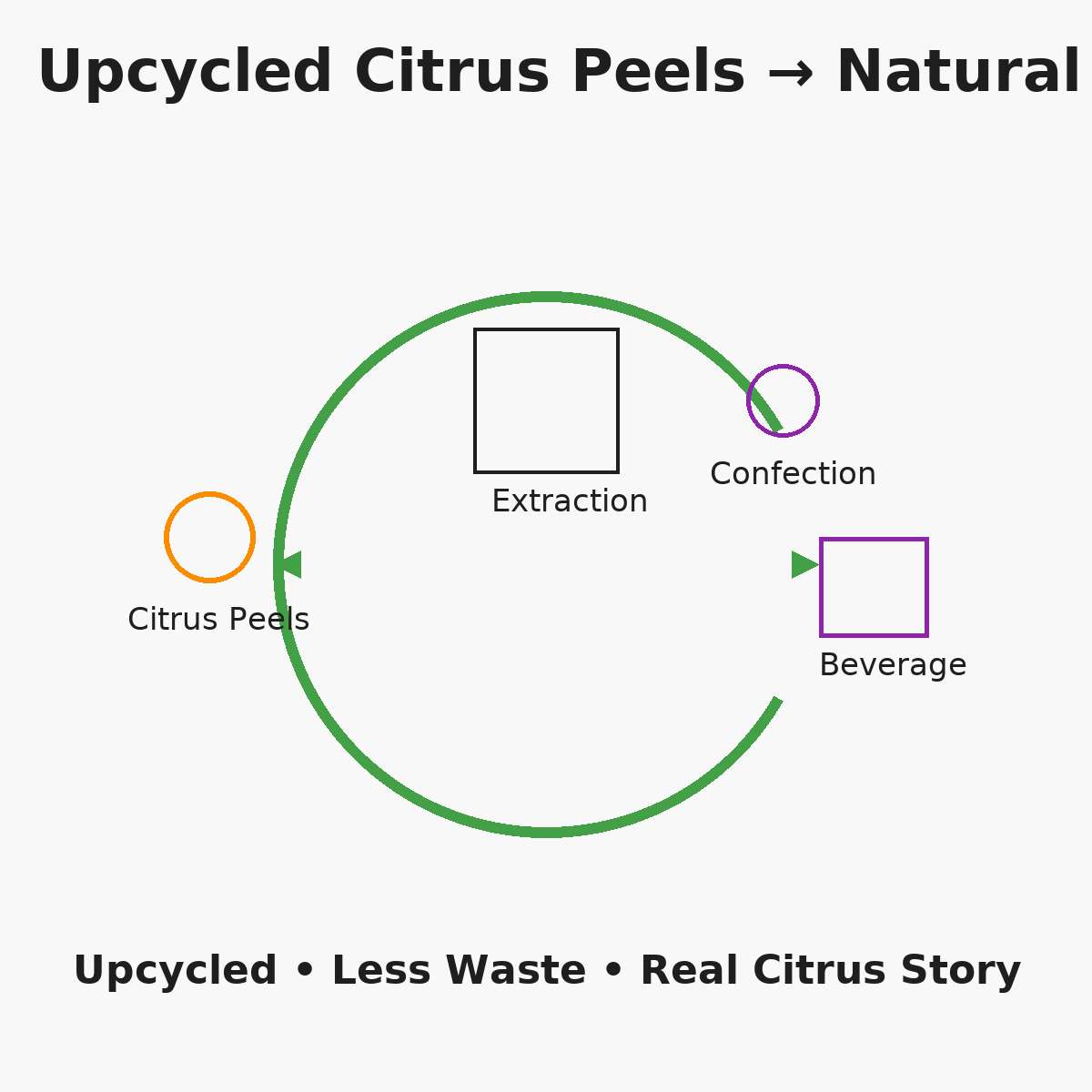

Keyword focus: upcycled ingredients, citrus peel oil, side-stream valorization, sustainability claims

Juice plants throw off peels and pulp that still carry oil and bioactives. Upcycling them reduces waste and gives you a real sustainability story. Also, it often pairs with antioxidant co-benefits in fats and confection.

Keyword focus: natural flavor definition, allergen labeling, “Contains” statement, flavor labeling rules

Tip: park a Regulatory Packet with every code: TDS, CoA, IFRA certificate, Allergen & GMO statements, Halal, ISO/GMP. Auditors love one-touch docs.

Keyword focus: Halal certification for flavors, IFRA Code of Practice, ISO 9001/22716, GMP traceability

Buyers ask three things: is it certified, is it traceable, will it be consistent next batch.

I’Scent holds IFRA, ISO, GMP, Halal; our ERP locks full lot traceability and batch-to-batch match.

Keyword focus: bitterness masking, flavor modulation, reduced sugar, plant protein off-notes

When you cut sugar or use botanicals, bitterness pops out. A targeted modulation system plus the right natural flavor oil smooths astringency, suppresses pithy notes in citrus, and keeps finish clean. Do your triangle tests early, not right before PP.

Keyword focus: bakery flavors, thermal stability, topnote retention, wholesale & custom bakery fragrances

Heat is the enemy of topnotes. Choose flavor oils with the right boiling profile and consider encapsulated options for cookies, cakes, fillings. Consistency on scale is key, or your SKUs eat returns.

Keyword focus: MOQ, lead time, batch consistency, ERP traceability, scale-up

You can’t scale flavor like a nice idea, you scale it with repeatability.

I’Scent offers samples in 1–3 days, production in 3–7 days, MOQ 5 kg (custom 25 kg). We match to 98% accuracy, and we keep that match. If you need flavor replication, we do it fast, then we lock specs so ops dont guess on the line.

| Trend / Keyword | Concrete Claim | What It Means For You | Lab / Ops Notes | Source Type (no external links) | Business Value Add |

|---|---|---|---|---|---|

| Clean label natural flavors | Shorter labels win shelf time | Prefer natural flavors with simple carriers | Check pH, heat, allergen | FDA 21 CFR 101.22, EU 1334/2008 | Faster approvals, fewer relabels |

| Essential oil nanoemulsions | Clearer drinks, smoother sip | Lower dose, better topnote placement | Track NTU, droplet size, 40/75 | Peer-reviewed reviews, internal stability SOPs | Less cost of quality, better repeat buys |

| Microencapsulation (spray drying) | Longer shelf, timed release | Dry mixes and bakery hold aroma | Validate aw, flow, payload | Manufacturing SOPs, COA/TDS | Fewer returns, uniform sensory |

| Supercritical CO₂ extraction | Solvent-free claim holds | Brighter aromatics, tighter spec | Confirm terpene ratio | Internal method sheets, IFRA | Premium positioning, cleaner story |

| Upcycled citrus peels | Real sustainability story | Supply from side streams | Verify residues, metals | Supplier audit checklist | ESG boost, retailer love |

| Halal/IFRA/ISO/GMP | Audit-ready docs | Faster buyer onboarding | Keep Reg Pack per code | IFRA Code, ISO/GMP manuals | Win more markets with less friction |

| Bitterness masking | Smooths reduced-sugar harshness | Keeps finish clean | Triangle tests early | Sensory SOPs | Better acceptance in low-sugar SKUs |

| Capability | What You Get | Why It Matters |

|---|---|---|

| 40,000+ formulas, 20+ senior perfumers | Broad starting points + fast edits | You prototype quicker, reduce rework |

| Customization & replication (≈98% match) | Fast “match & improve” | You keep brand identity while fixing pain |

| Lead times | Samples 1–3 days, production 3–7 days | Short cycle, more iteration, less idle line time |

| MOQs | 5 kg standard, 25 kg custom | Pilot to launch without inventory stress |

| Certifications | IFRA, ISO, GMP, Halal | Audit smooth, multi-market ready |

| Traceability | ERP end-to-end | Quality by Design, stable spec |

| Formats | Nanoemulsions, spray-dried, oil-soluble | Choose form by matrix and process |

| Sectors | Beverage, bakery, confectionery, dairy-alt, instant | One partner, many categories |

(Need a one-pager for buyers? Point them to I’Scent or the OEM/ODM Fragrance Oil & Perfume Raw Materials Manufacturer overview.)

I know, sounds obvious. But teams often chase magic bullets, then wonder why panel scores drift. Keep your matrix physics and process map in the room.

Keyword focus: TDS, CoA, IFRA certificate, Allergen statement, Halal certificate, ISO/GMP

I’Scent keeps the pack ready so procurement doesn’t ping-pong emails before signoff.

Keyword focus: Wholesale & Custom Bakery Fragrances, thermal stability, crumb interaction, fat phase

Bakery sits hot and oxygen-rich. If topnote burns off, your product tastes generic. Build layered flavor: base in the fat phase for body, topnote encapsulated for post-bake release. For fillings and icings, watch water activity so flavor migration doesn’t wash out your surface note.

Browse Wholesale & Custom Bakery Fragrances | Tailored Scents for Your Creations for ready-to-go profiles, then we tune them to your flour, fat, and sugar systems.

None of those are hype, they’re shop-floor reality. You can sense it in your rejection rates and repeat purchases.

Titles using real keywords

Writing angles & talking points

Data cues (no external links)

Tone to mimic

We run OEM/ODM since 2005 and supply 40,000+ fragrance formulas worldwide. The team includes 20+ senior perfumers, and yes, we replicate down to a ~98% match when you need keep-the-same-but-better. IFRA, ISO, GMP, Halal? In place. ERP traceability? End-to-end. You get samples in 1–3 days, production in 3–7 days, and MOQ 5 kg (custom 25 kg). That’s quick enough to keep your commercial window open.

If you’re building Food & Beverage or Bakery lines, bookmark these: